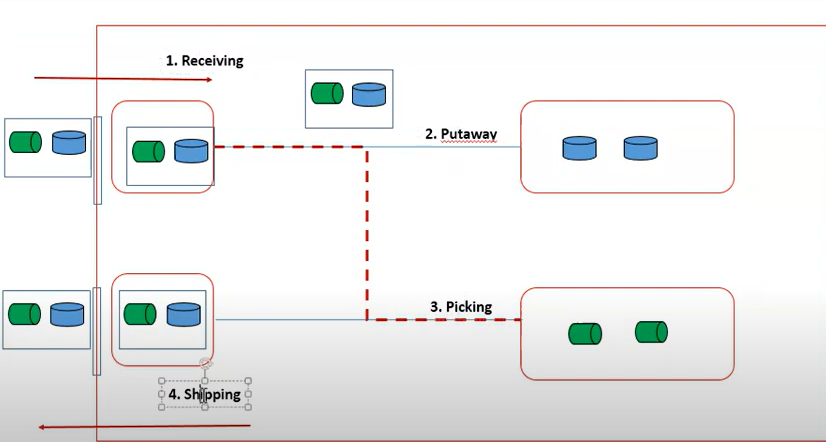

It is a key part of supply chain and primarily aims to control the movement and storage of material within a warehouse and process the associated transactions, including Receiving,

Put-a-way,

Picking and

shipping.

A WMS monitors the progress of products through warehouse. It involves the physical warehouse infrastructure, tracking system and Communication between product stations.

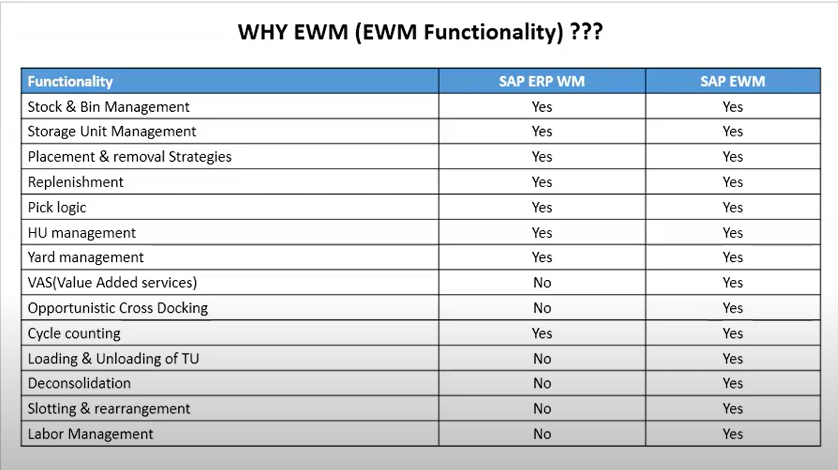

SAP WM VS SAP EWM

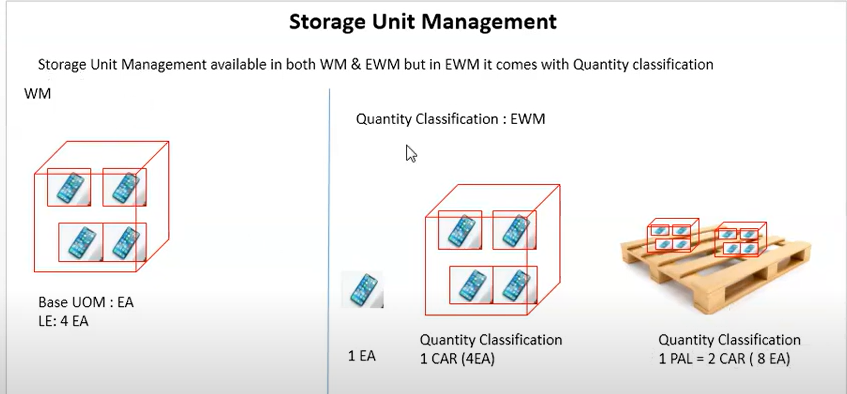

Storage Unit Management

Storage unit management is available WM and EWM it comes with Quantity Classification

Put a way and Removal Strategy

–> put a way material is based on size, shape types etc. e.g. electric parts, fastener, engine part, bumper etc.

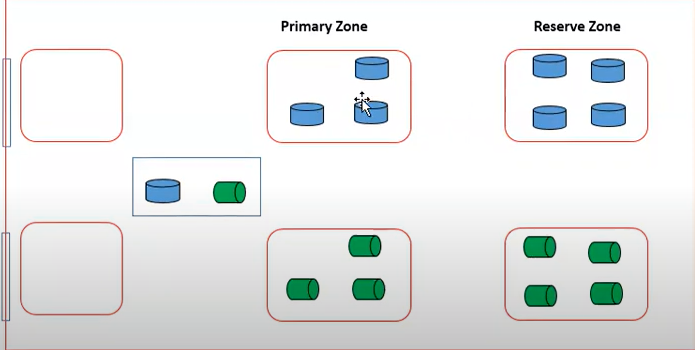

Replenishment

–> for optimization of time and delivering orders quickly.

–> if the configuration is done for Replenishment the it will take the goods or materials from the Reserve zone and put it in the primary zone empty space.

–> removal strategy : to pick materials as quick as possible

From reserve zone to primary zone.

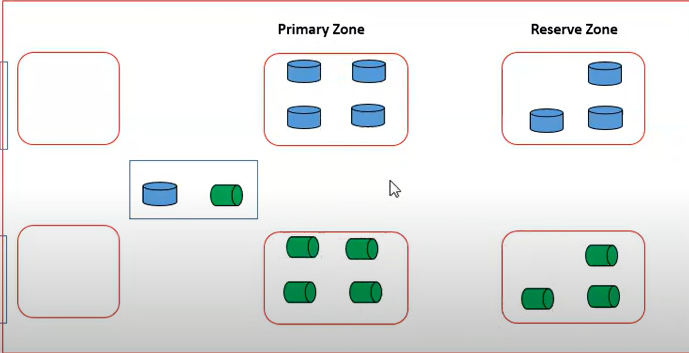

This strategy can be defined at bin level or at storage type level.

If I define at bin level then I have to define the maximum and minimum quantity.

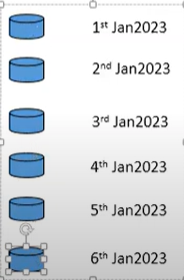

Pick Logic.

Logic to pick the products

- LIFO –> Last in Fast Out.

- FIFO –> First in First Out

HU management

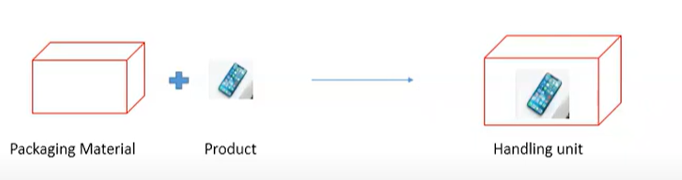

Handling Unit : A Packaging Material + Product with a unique ID no

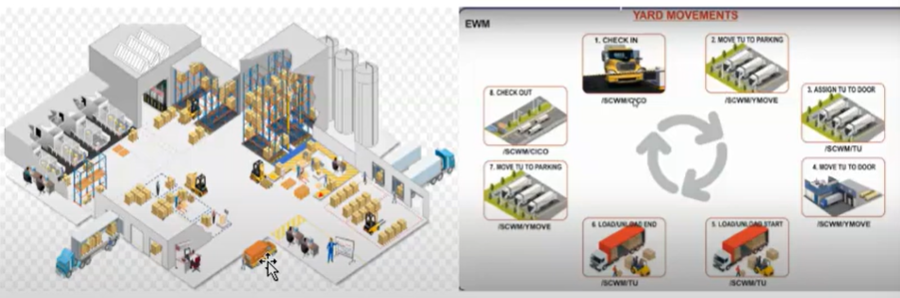

Yard management

It represents an enclosed area outside the of warehouse where vehicles are check IN/Check out, Park, assign warehouse doors for loading & Unloading activity.